The year brought us impactful conversations, memorable moments, and a peek into the future of technology. We explored intriguing topics, including AI for bone health, the SwRI-led PUNCH mission, fuel testing for quality and safety, the possibilities ahead with 6G technology and more. We heard special “listen and learn” moments with every episode. Now, let’s rewind and review 2025 and hear from the experts that shared their knowledge and stories with us.

Listen now as podcast host Lisa Peña recaps 2025 and takes us through the enlightening, inspiring conversations of the year. For all episodes, complete transcripts and photos, visit Technology Today Podcast.

Transcript

Below is a transcript of the episode, modified for clarity.

Lisa Peña (LP): We are closing 2025 smarter, more informed and inspired thanks to the SwRI experts who joined us on the podcast this year. We explored a range of fascinating topics, including AI analysis for bone health, user-friendly robotics software, recycling CO2 waste into a valuable product and more. We are rewinding and reviewing 2025…next on this episode of Technology Today.

[MUSIC PLAYING]

We live with technology, science, engineering, and the results of innovative research every day. Now, let's understand it better. You're listening to the Technology Today Podcast presented by Southwest Research Institute. From deep sea to deep space, we develop solutions to benefit humankind. Transcript and photos for this episode and all episodes are available at podcast.swri.org. Share the podcast and hit that subscribe button on your favorite podcast platform.

Hello and welcome to Technology Today. I’m Lisa Peña. It was a busy and productive year at Southwest Research Institute, and our podcast guests caught us up on some of our impactful projects and achievements of 2025.

We learned about the SwRI-led PUNCH mission, just before it set out to capture never-before-seen images of the Sun’s corona transitioning to the solar wind.

We discussed advanced electronic warfare technology developed in our new Georgia facility, the first SwRI-owned property outside of Texas.

We heard about the award-winning compressor and engine, both co-developed by SwRI and recognized with “Oscars of Innovation.”

Every episode brought us special “listen and learn” moments.

So, Let’s get into our 2025 rewind!

We launched the year with Highlight™, a machine learning tool used to search for chemicals in consumer products.

In January, SwRI analytical chemist Dr. Kristin Favela and Chemical Engineer William Watson discussed how Highlight illuminated the data in a revealing study.

LP: Did you find a type of product or clothing or upholstery that you think was most risky?

William Watson (WW): In general, the rubber products were riskier than the fabrics, clothing, upholstery. So things like rubber playmats or tires, those kind of things tend to have more possibly unpleasant chemicals in them.

Kristin Favela (KF): Yeah, that's correct. So, some of the products were recycled tire products that get used on playgrounds and things like that. And those did have a lot more chemicals in them. And those materials are also known to be sort of absorbent. So, they pull things out of the environment and then may re-emit them.

LP: Oh, okay. Yeah, that's interesting. But again, this was finding those chemicals and figuring out whether or not they could be emitted or extracted, but not necessarily what their impact is on human health yet.

KF: Correct. So, all of this data is going into EPA's models to answer that really important question about human health. Again, if you don't know what's there no one has unlimited resources. So there needs to be a sort of triage process. So, what chemicals should we be most concerned about? What chemicals have the most potential for being toxic and/or are present at highest levels?

The study was conducted in collaboration with the Environmental Protection Agency and was published in the Environmental Science and Technology Journal.

And on to February…

Before the launch of NASA’s Polarimeter to Unify the Corona and Heliosphere or PUNCH mission, led by SwRI, we learned about the satellites and instruments set to capture the first images of the solar wind.

SwRI space scientist, heliophysics expert and PUNCH Principal Investigator Dr. Craig DeForest spoke about where PUNCH was headed.

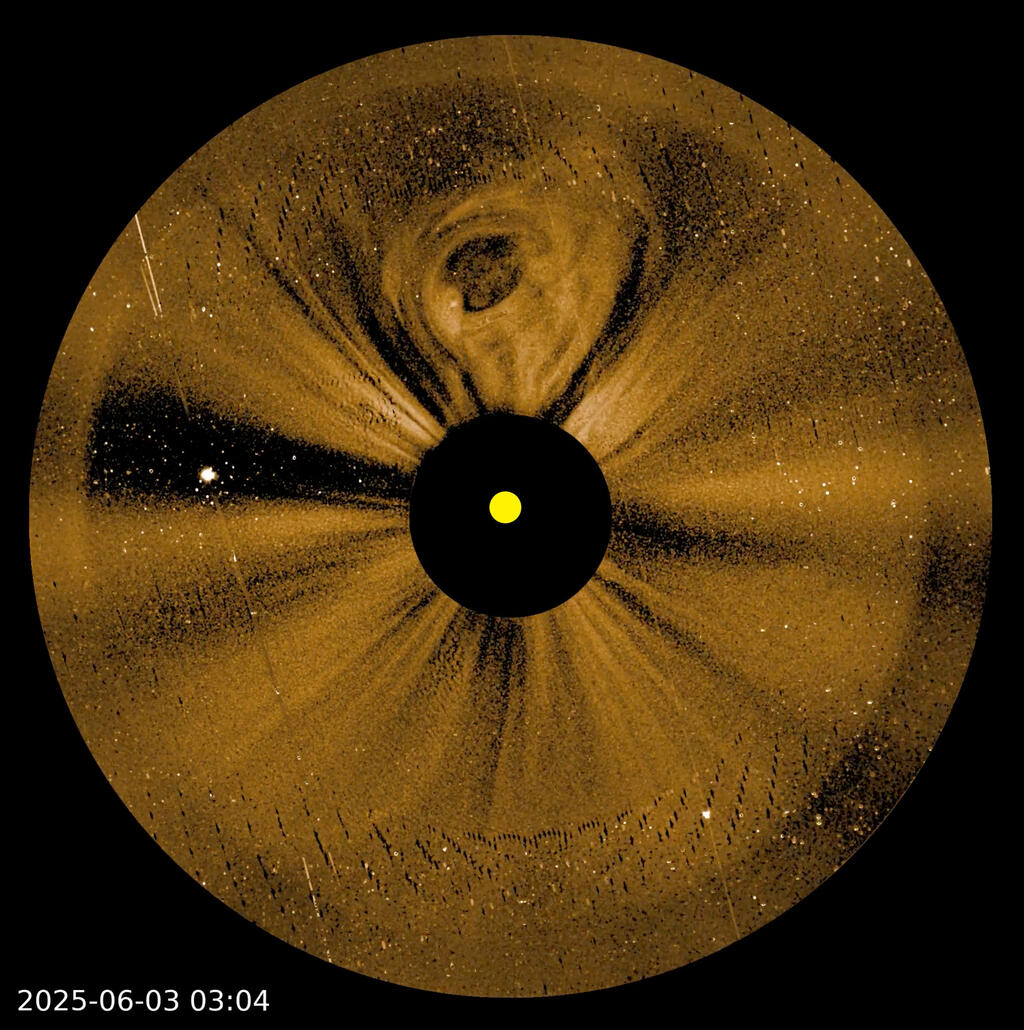

Image

NASA’s PUNCH mission, led by SwRI, used its Narrow Field Imager (NFI) to collect images of solar activity. A June 3 coronal mass ejection shown at the top of this image grew to enormous size, 100 times that of the Sun, as it traveled across the solar system. We learned about PUNCH before its launch in March on Episode 76.

LP: So, the PUNCH constellation of satellites, as you've mentioned, will be in low-Earth orbit. What does that look like, and what else can you tell us about where the satellites will be positioned?

Craig DeForest (CD): PUNCH is launching into low-Earth orbit. That means we'll be about 400 miles above the surface of the Earth, just above the atmosphere, so that we can move fast enough to remain in orbit. In order that we can see the sun all the time, we're in something called a sun synchronous dawn dusk orbit.

Now, when you think on a planetary scale and you think about orbits, sunset is not a time. Sunset is a place. So, we are always right over that sunrise-sunset line on the planet as we orbit around in a polar orbit. So, we go from north to south, skimming that line so that every spacecraft is always in the sun, looking sideways out across the Earth toward the star itself.

LP: I may never forget that. Sunset is not a time. Sunset is a place. And that's where PUNCH is going. Amazing. Okay. So how do you know this is going to work? How do you know that you can go up there and get these images of the solar wind? What here on Earth tells you that this is the way to do it, this is going to work?

CD: Like every mission, we are standing on the shoulders of giants. This type of measurement has been tested before. There's a mission called STEREO that prototyped an imaging system similar to our wide-field imager.

STEREO was a first cut, so it wasn't able to produce the kind of detail or the three-dimensional images that we will be seeing, and it didn't look all the way around the sun to view the solar wind as it washes over us. But we were able to demonstrate, using the STEREO data, that we would be able to extract the images that we plan to with PUNCH.

PUNCH launched on March 11 and is already sending back data and images, including recent captures of coronal mass ejections.

SwRI developed artificial intelligence for enhanced bone imaging to give patients a clearer picture of bone health.

In March, SwRI biomechanical engineer Dr. Lance Frazer explained how it works.

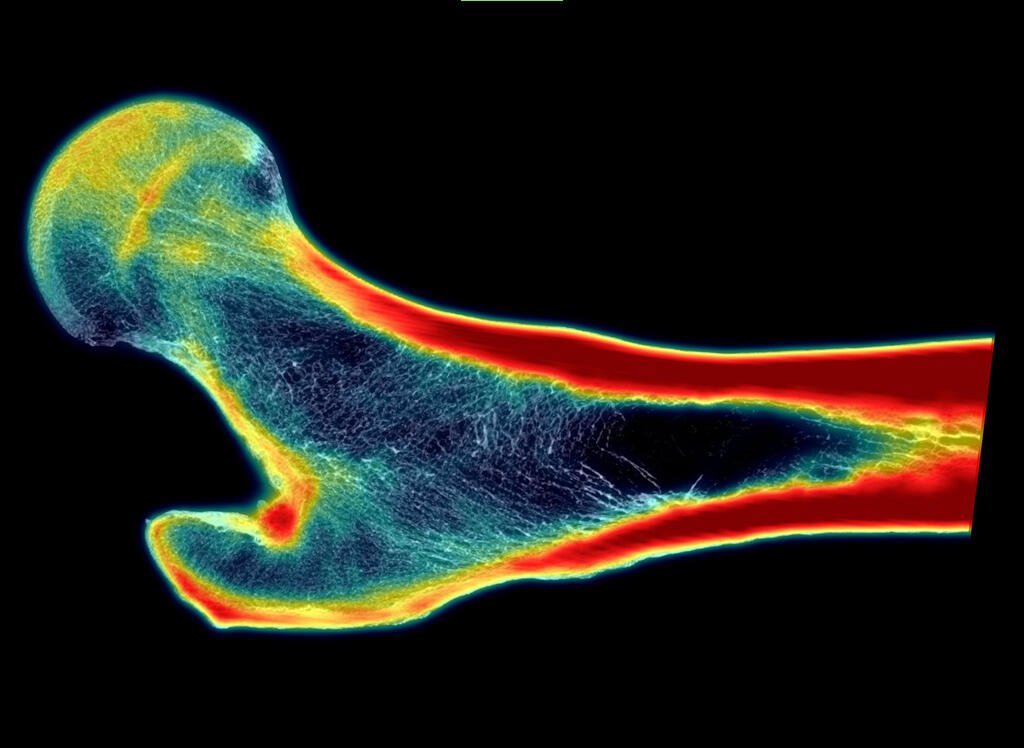

Image

SwRI’s super-resolution technology, which uses artificial intelligence to create higher-resolution images from CT scans, produced this image of the femur microstructure. Clear AI images like this could help physicians better assess osteoporosis and fracture risk in patients. We discussed the technology on Episode 77.

Lance Frazier (LF): How we do this is we have, here at SWRI, what's called a micro-CT scanner, and it can provide incredible resolution. And so, we have a whole freezer full of bones.

LP: Just for clarity's sake, where do you get a freezer full of bones?

LF: Yeah, where do you get freezer full of bones? When people donate their bodies to science, people can do great things with them.

LP: Okay, so these are real human.

LF: These are real human bones that we are the beneficiaries of receiving, and we are trying to better human health with them. So, we are very appreciative that people donate their tissues to science. So, we have a micro-CT here.

This provides incredible resolution. You can see every single detail of the bone that you'd be interested in, at least for biomechanics. But you can't do that kind of a scan in a clinic.

The radiation that you subject these bones to is way, way, way too high. So, it's not even on the table for clinical scans. But what we can do is we can take this freezer full of bones, image them here at the institute with our micro-CT, and then also imaged those same bones on a clinical CT scanner.

And then we say, okay, here's a picture of a bone from a clinical CT scanner, and here's that same bone from a micro-CT. And then you teach AI to look at that clinical scan and just improve its image quality to look like what it would have looked like had you scanned it with a micro-CT. So, you're teaching AI to take that clinical scan and essentially upgrade it to a micro-CT scan that you cannot get in a clinic.

LP: And after it sees these images repeatedly like, this is the image we start with. But this is how clear we want it to be. It pretty much can do it itself. It takes over and is able to fill in the blanks itself.

Dr. Frazer described bones as adaptable, living and smart and recommended weight bearing exercises for stronger bones.

In April, we learned about the SwRI Workbench for Offline Robotics Development™ or SWORD™.

SWORD developers Matt Robinson and Michael Ripperger told us how the software is simplifying robotics motion planning.

Matt Robinson: So what can we do to enable folks that are like, say, getting into robotics? They are CAD savvy and good. They know their traditional industrial robotic systems, but they're not really ready to go full on C++, manipulating point clouds, like under the hood, these things that Michael and his team do all the time.

But can we give them some sort of a springboard to get there and start like experimenting with, basically, these robots that almost program themselves? So, no more point-to-point program, but setting up what we call motion planning, where the system can say, understand what's going on in its environment. And I can resolve and make these motions without, say, having to do like the point-by-point program, which was the old way of doing it.

And that acceleration or getting people to the point where they can start seeing the real value of when we say advanced capability, i.e. things like autonomous motion planning, then they'll continue to improve their own skills. But they have that nice starting point that meets them where they are. And I think that's what's been really exciting about where SWORD has gotten.

Lisa: Okay, let's talk about motion planning for a minute since you mentioned it quite a bit. So, describe it for me. What is a scenario in which motion planning comes into play?

Micheal Ripperger: Yeah, I'd say for just any sort of industrial application, be it like sanding or grinding, you have a part. And you have some points on that part where you need to take a tool, like a grinder or sander or a paint gun, you need to move over your part and do some sort of task. And so, you've got these points that exist sort of in 3D space on your part.

But then, you need to figure out how does the robot need to move its joints, such that it takes that tool and performs a process that you care about? And that's what we're calling motion planning, is this process of figuring out how you move your robot to do a task, while also thinking about all sorts of other different things. How do I not run into anything and cause a crash?

Visit sword.swri.org to learn more about the user-friendly SWORD robotics toolkit.

SwRI is working on a large-scale solution to turn carbon dioxide waste into graphene used in electronics, biomedical devices and more.

In May, we heard from SwRI Chemical Engineer Michael Hartmann and Scientist Miles Salas about the push to scale up production of valuable graphene.

Image

Using internal research funding, chemical engineers at Southwest Research Institute developed a multi-step process to produce graphene, a valuable carbon allotrope, from carbon dioxide. The graphene, which is suspended in a fluid, is useful for a variety of applications. We explored converting CO2 waste into graphene on Episode 79.

Miles Sales (MS): But because nobody can really make graphene, bulk graphene production is usually valued in terms of kilograms, so that's 1,000 times smaller than tons.

And I've seen dollar estimations of graphene materials in platelet form, which is what we're making, ranging from \$2,000 per kilogram up to \$10,000 per kilogram, which means you're at a tonnage scale. You're looking at hundreds of thousands of dollars per ton or even millions of dollars per ton. So that's a pretty big driver.

LP: All right. So no one can make it on a large scale. Is SwRI trying to change that?

MS: Yes. So that's one thing we're trying to do, at least with this project. We're in the very early stages. But we do plan to start scaling up the process to try to bring it into a much larger scale.

But one thing about this reaction is we're not necessarily limited by our reactor size. And the reaction itself should be very scalable because that's what we're trying to show with this.

LP: So what's the plan to scale it up?

Michael Hartmann (MH): Yeah, on our side, our scale right now, we are in maybe about a 100-gram reactor size. So, we're still relatively small-scale. But when we were looking into this process, we were specifically looking at what other industries already have existing large-scale commercialized operations that we can apply.

So, our reactor technology, it's very basic. It's just basically a heated stirred melt reactor, if you call it that. So it's just electrically heated. But the unique thing for our process specifically is looking at some of the sparging dynamics, so how to distribute these CO2 bubbles in this reaction.

The carbon dioxide used in this process has been captured to reduce greenhouse gas emissions in the environment. Using it to produce a valuable product like graphene is an alternative to storing it indefinitely.

SwRI has conducted fuels and lubricants research since the late 1950s. Decades later, the program continues, analyzing today’s fuels while looking ahead at fuels of the future.

SwRI Fuels and Lubricants Research Director Robert Legg discussed testing fuel for quality and safety.

LP: So, when we're talking about conventional fuels that we use every day, do you test batches of fuel before they are sold or are you testing fuel that is already publicly available?

Robert Legg (RL): Well, we actually do both. The majority of our testing is really from the retail outlets. Our section, my departments they're really in a unique position that we have a network of contractors throughout the nation, and even some of the U.S. territories, that can collect fuel from just about any gasoline station in the nation. We'll actually send them a kit. They'll take that kit to the gas station, fill it from the pump, just like the same fuel that you're putting in your car. They'll close up those containers and ship them back to us for testing.

So, what we're ultimately trying to do is to evaluate the same fuel supply that the customer is seeing in their tank. And then, of course, we also work with the fuel manufacturers and other partner labs to collect samples from either the refinery or the terminal tanks to look at the fuel or even the fuel blendstocks, the components that are used to make the final product fuel that goes into the gas station.

LP: So, you're testing some as you said, you're testing some before it goes out and some that's already out there. And that's really neat. You're collecting these samples from all over. And this is actual gas people are buying, people buying this gas. And you're checking to see if it's good to go, if it's safe, if it's of quality. So, what happens if you find a bad supply in these samples that come in?

RL: Well, surprisingly, that doesn't happen that often.

LP: That's good to hear.

RL: The fuel pool within the United States is pretty much within specification. But there are a few occasions where that does happen, like we've seen where there may have been too much ethanol put in the fuel or the vapor pressure was a little bit outside of the specification. Most of the time, these little instances, these little excursions, will not have any sort of impact on the consumer. But I can tell you that the refiners and the retailers take them very seriously.

And for your next trip to the pump, Legg shared his top tips for filling up, which you can hear on Episode 80.

NASA's OSIRIS-REx mission collected rocks and dust from the near-Earth asteroid Bennu.

In July, SwRI’s Dr. Vicky Hamilton, an OSIRIS-REx Instrument Scientist and Mission Co-Investigator, shared an update on what the mission uncovered.

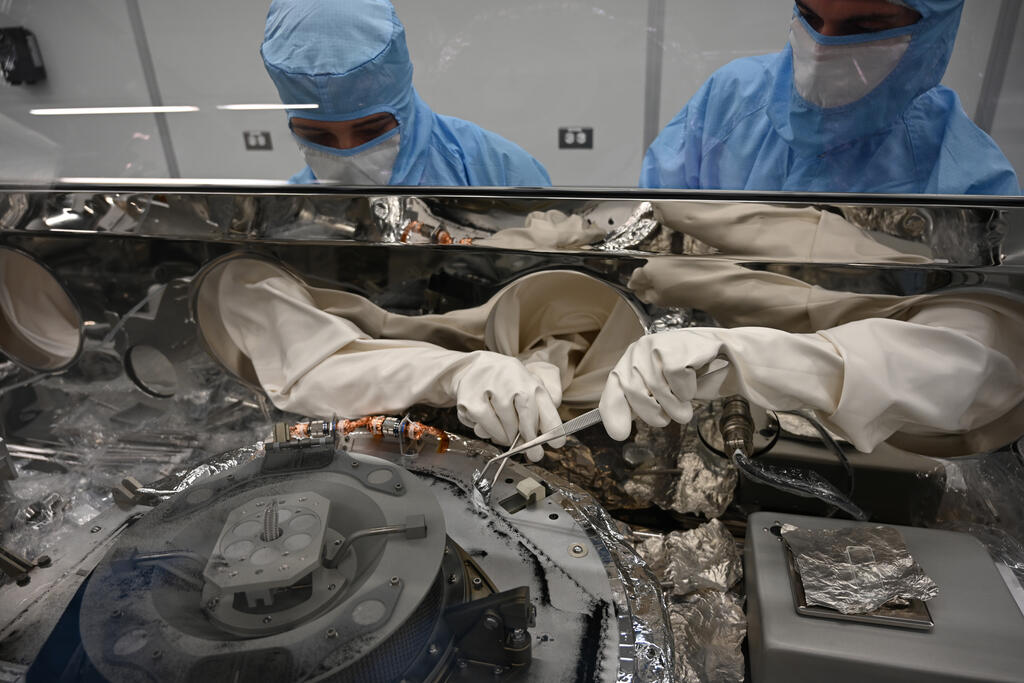

Image

NASA’s Origins, Spectral Interpretation, Resource Identification and Security – Regolith Explorer (OSIRIS-REx) mission returned to Earth in September 2023 to drop off a sample of rocks and dust from the near-Earth, carbonaceous asteroid Bennu. The untouched sample of rocks and dust from the surface of the asteroid was transported to a clean room for processing. Hear about OSIRIS-REx and Bennu on Episode 81.

LP: Then the big question. What did the team find in the sample?

Vicky Hamilton (VH): We found all kinds of things, things we thought we'd find and things we didn't think we would find. So, we found a lot of what we call volatiles. So, this is things like carbon, nitrogen, ammonia. And more than we were accustomed to seeing in the meteorites that we have here on Earth. We were able to find that a lot of that formed in a very cold location or further away from the sun than the asteroid currently is in its orbit.

We found minerals that we had never seen in comparable meteorites. And so, the team has just been ecstatic with what we found, what we got.

LP: So yeah, you said you found some things you thought you'd find. Others, you were surprised to find. So, what was your most surprising finding?

VH: There are two that stand out in my mind. One of them is about the organic chemistry that is in the sample. Some folks may be familiar with the idea of chirality, or left or right-handedness in chemical compounds. And on Earth, almost all of our life is what we call left-handed. And we assumed that the sample we got back, that everything else out in our solar system would be like that.

Except it turns out, that's not the case. In Bennu's case, all of the amino acids that were not proteins basically were roughly equally left-handed and right-handed.

Scientists studying the Bennu sample continue to find new clues about the formation of the early solar system, including sugars essential to life, a gum-like substance and dust produced by supernova explosions.

In August, we learned about SwRI’s NEXTCAR platform, an energy saving software suite that uses algorithms to increase fuel efficiency while reducing emissions.

SwRI engineer and NEXTCAR program principal investigator Stas Gankov explained the advantages of a personal NEXTCAR driving experience.

LP: How does NEXTCAR use CAV technology to achieve that efficiency, to reduce energy consumption and emissions?

Stas Gankov (SG): NEXTCAR is a suite of technologies that targets different parts of the vehicle, of the existing vehicle platform, and it uses different methods, different mechanisms to achieve energy efficiency without relying on any hardware changes. There are different techniques like eco driving, eco routing, power split optimization, lane change assist, merge assist, platooning. All of these are different techniques that can allow the vehicle to operate more efficiently.

Using the information from the surroundings through connectivity and through automation can enable us to make use of and tailor these techniques specific to that vehicle and make them more likely to save energy and more likely to save fuel than if we were to just allow the vehicle to not have any insight into the kind of environment that it's in, the kind of drivers, the kind of driver that we have behind the wheel. This is actually something that doesn't rely necessarily on human input, and it's really just trying to solve these different optimization problems.

And with optimization, what we're trying to do is we're trying to create and solve these complex problems that have a lot of constraints. So, you have, for example, your constraint as a driver with how close you can follow another car. You are also constrained with how quickly you can accelerate and decelerate. And you're also constrained by traffic lights that you're encountering.

What NEXTCAR allows us to do is to use all that information and create the most optimal speed that the car needs to travel. Let's say if you're approaching a traffic light, you don't want to necessarily stop at the red light and then have to accelerate a second later because the light changed to green. If you knew the information ahead of time, you might be able to slow down before approaching the light and then cruise on through that light as soon as it changed to the green state.

NEXTCAR works with all vehicles — electric, hybrid or conventional — without changing the engine or hardware.

For the first time in its 78-year history, SwRI built an office outside of its Texas headquarters in Warner Robins, Georgia, to support Air Force and national defense advancements.

In September, we spoke to SwRI’s Winfield Greene, David Brown and Jarrett Holcomb about the research and development underway in the new Georgia facility.

LP: What are engineers and researchers working on in Warner Robins?

Winfield Green (WG): Well, electronic warfare is a little bit difficult to explain, but the easiest way to explain it is that it involves signal processing, where we receive enemy radar signals, we process those signals to understand them, and then we compare them to known radar signals. And then we have responses that we send back to confuse the enemy, so that the enemy will not be able to fire their missiles at that Air Force assets or Navy assets or Army assets.

LP: So, what is cognitive electronic warfare?

David Brown (DB): So cognitive electronic warfare has the idea of placing some human cognition, some human reasoning into the electronic warfare process. For example, cognitive electronic warfare system would typically autonomously sense the environment, which would allow it to develop an understanding of the threat situation around the aircraft or around the vehicle, make independent decisions for an appropriate response as necessary, and then be able to put those decisions that it makes into action and determine if the action that it has taken has the desired effect, and if not, the cognitive system can actually adjust what it's doing in order to improve performance.

LP: How do SPARTA and ATHENA contribute to the important SwRI mission of research and development to benefit humankind? What is your take on that?

Jarrett Holcomb (JH): So I think that both of these, and specifically, when we talk about researching electronic warfare, I take extreme pride in the fact that what I'm doing is affecting warfighters' lives. The whole mission behind electronic warfare, in general, is to protect these warfighters against some really dangerous technology and weapon systems that are going after some of these warfighters, and they're using the spectrum to try to do that.

We're using the spectrum, using SPARTA to evaluate electronic attack tools in order to make sure that that pilot comes home safe and using ATHENA in order to detect these really dangerous signals a lot faster.

Visit ew.swri.org to learn more about SwRI defense and electronic warfare capabilities.

October brought a special celebration of two award-winning technologies co-developed by Southwest Research Institute.

SwRI engineer and manager, Ryan Williams told us about an engine for medium-duty trucks and SwRI Engineer and senior manager, Dr. Jason Wilkes explained the special features of an oil-free centrifugal compressor.

The technologies received 2025 R&D 100 awards known as Oscars of Innovation and were recognized as two of the most significant technical accomplishments of the year.

LP: OK, so oil-free is in the title, the Copeland Oil-free Centrifugal Compressor. Why is this an important characteristic of this technology?

Jason Wiles (JW): Oil has been used in refrigeration systems for a long time, mainly because there was moving parts, bearings, seals, that performed better with the oil. Because this is in a closed-loop system, where you essentially compress the fluid, reject the heat, expand the fluid, then you do cooling of your atmospheric air or the water, and then you come back through your compressor.

The problem is that oil migrates throughout your system and ends up in a lot of places where it's not really desirable. So the oil ends up clogging up avenues in the cold side of your system, and it's really unfavorable. So, the notion that this has zero oil in it is really advantageous to pretty much everybody that works in refrigeration systems.

LP: Let's talk about the Low Mass, High Efficiency Engine that won the award. What makes this a unique solution for medium-duty trucks?

Ryan Williams (RW): Like the name suggests, there's two pieces to this. There's the low mass piece of it, and the high efficiency piece of it. So, the low mass was really focused on bringing down the weight of the engine. Because the application that these engines go into are so demanding, they tend to be pretty beefy engines with big cast-iron blocks and cranks that just really heavy components.

And so the low mass piece of this project was focused on bringing that down and bringing in some of the technologies from light-duty, like aluminum alloys and aluminum casting and new casting and forging techniques to help reduce the mass of the engine. And then the high efficiency side was focused more on still retaining the power and torque that these engines need to make to be effective but using less fuel as we do that.

SwRI has won 54 R&D 100 Awards since 1971.

And just last month, SwRI RF Sensors and Systems Department Director and our in-house 5G expert Jody Little told us about the campus’s new, private, secure, high-velocity 5G network and what could be possible with Future G connections.

LP: So what are some applications for everyday users that 6G and beyond might bring us?

Jody Little (JL): Well, for everyday users, one of those would be being able to do real-time gaming right on your phone with virtual reality and high-speed gaming.

LP: Oh, OK, there you go.

JL: So right now, the PS5s and the other devices are actually you could think of them as edge devices. So you're connecting through the backhaul, bringing it down, and running on them. But this will allow it to be done across the ecosystem, rather than having to have separate capability to do it. So, you'll be able to connect augmented reality through it.

One of the things that they're looking at for future G and 6G, they're already doing this, but future G will have enough bandwidth and quality of service to support holographic TelePresence, which is a lot of that.

LP: Woah, Yeah.

JL: And so you've seeing that, but it takes a lot of bandwidth to do that. But the future 6G will be able to do that. And it sounds like, wow, future, but it's a pretty big deal where you can be sitting in a meeting that's somewhere else, instead of just on a screen, you're actually sitting in that meeting holographically. And there's already some demos out there on the web of that. So that's kind of growing.

Enable digital twins for entire cities. So, we're actually working with some of the University-owned digital twin for 6G and have worked with UTSA and others to bring 6G digital twin to support doing research and development before we ever put a device in there.

So that allows more research to be done within that 6G digital twin, before you spend a lot of money putting a lot of infrastructure in place. So, we're seeing that.

And then intelligent automation is going to be another big one. We're already starting to see that, as well. You're seeing it in our everyday life. But you're going to see more and more intelligent automations. So that robot future, the robot takeover, is coming down and being driven by the communications capability.

LP: All right, and you're helping to make it happen, Jody.

OK, so future G, we're talking about high-level military operations, all the way down to talking to a hologram of grandma instead of FaceTiming her.

The private 5G network operates with infrastructure on campus or in the field with portable equipment.

And that was 2025!

Thank you to our SwRI scientists, engineers and experts who took us behind the scenes and shared their insight and stories.

You all made it a great year on the podcast!

And thank you to our listeners for learning along with us today and throughout the year!

You can hear all Technology Today episodes and see photos and complete transcripts at podcast.swri.org.

Remember to share our podcast and subscribe on your favorite podcast platform. Want to see what else we’re up to? Connect with Southwest Research Institute on Facebook, Instagram, X, LinkedIn, and YouTube.

Check out the Technology Today magazine at technologytoday.swri.org and now is a great time to become an S-W-R-I problem solver. Visit our career page at SwRI.jobs.

Ian McKinney and Bryan Ortiz are the podcast audio engineers and editors. I am producer and host, Lisa Peña.

Thanks for listening!

[MUSIC PLAYING]

The Technology Today Podcast launched in November 2018, offering a new way to listen and learn about technology, science, engineering and research impacting our lives and changing our world.

How to Listen

Listen on Apple Podcasts, or via the SoundCloud media player above.